Unleashing Efficiency: How the Right Flow Control Valve and Advanced Control System Optimize Process Control

2025-11-27As a factory owner who has spent years walking the floor of my own production lines and discussing the intricacies of hydraulic systems with clients worldwide, I know that the difference between a profitable operation and a chaotic one often comes down to control. Specifically, valve control. Whether you are managing a massive oil and gas refinery or a compact mobile crane, the ability to direct, stop, and regulate the flow of fluids is the heartbeat of your business. I've seen firsthand how the right components can transform a jagged, inefficient process into a smooth symphony of productivity.

This article is written for professionals like you—procurement officers, engineers, and business owners who need to understand the nuts and bolts of process control. We will dive deep into the world of the control valve, exploring how flow control works, why it matters for safety and efficiency, and how to select the perfect valve for the job. By the end of this guide, you will have a clear roadmap to optimize your systems, ensuring reliability and maximizing your operational potential.

What is the Cornerstone of Process Control in Modern Industry?

If you strip away the complex electronics and the massive steel structures of any industrial plant, you will find that the cornerstone of process control is the humble valve. In any industrial process, materials must move from point A to point B. This movement requires a gateway, a mechanism to start, stop, or throttle the flow. This is the valve. Without it, process control is impossible. A control system might be the brain, sending signals and making decisions, but the valve is the hand that actually does the work.

In my interactions with buyers like Mark, I often explain that valves serve as critical components because they are the physical interface with the product. Whether that product is water, chemical slurries, or volatile gas, the valve must contain it and manage it. A high-quality industrial valve ensures that the process runs within its design parameters. If a valve fails, the process stops, or worse, becomes dangerous. Therefore, the reliability of the entire plant rests on the shoulders of these components.

To optimize performance, one must view the valve not just as a piece of metal, but as a dynamic element of the control loop. The valve position determines the flow rate, pressure, and ultimately, the quality of the final product. Process stability is achieved only when the valve performance matches the demands of the control system. In essence, you cannot have a modern, efficient factory without mastering valve control.

How Do Flow Control Valves Actually Regulate the Flow of Fluids?

Understanding how flow control valves work requires looking at the physics of fluid flow. At its simplest level, a flow control valve works by changing the size of the opening through which the fluid or gas passes. By restricting the passage, the valve creates a pressure drop. This resistance slows down the flow rate. It is similar to putting your thumb over the end of a garden hose; you change the flow and pressure by altering the opening.

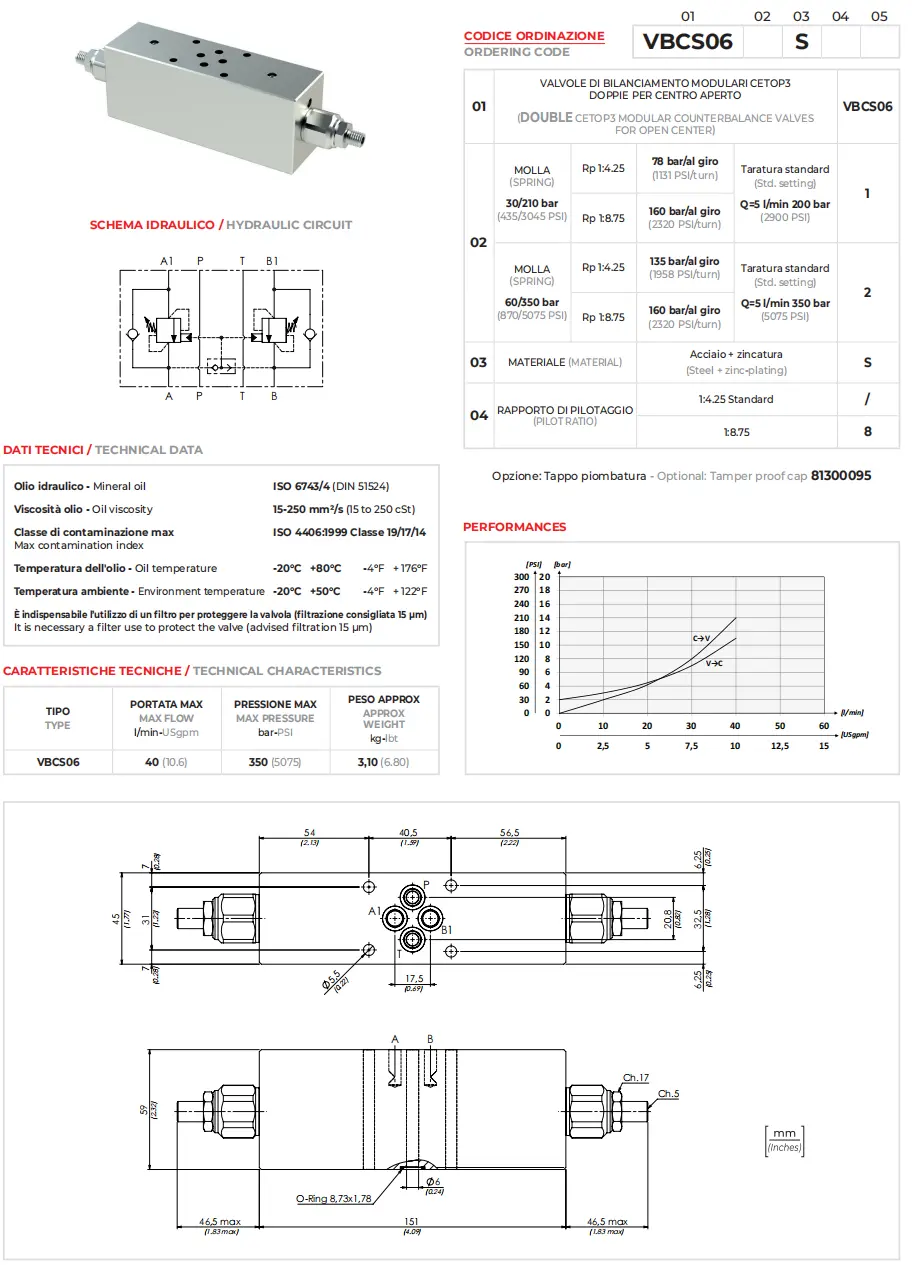

Flow control valves are essential because they allow operators to maintain the desired flow rate regardless of changes in the rest of the system. For example, in a hydraulic system, if the load on a cylinder changes, the speed would naturally change. A sophisticated flow control valve, like our Modular One Way Flow Control Valve, compensates for these fluctuations to keep the movement steady. They regulate the flow by dynamically adjusting the internal orifice size, ensuring consistent output.

The mechanism inside can vary. It might be a needle moving into a seat, a ball rotating, or a spool sliding back and forth. Regardless of the design, the goal is precise control. The ability to fine-tune the amount of fluid or gas passing through the system allows for the detailed regulation necessary for complex tasks. Valves provide the modulation that turns raw power into useful work.

Why is Precise Flow Control Critical for Oil and Gas Operations?

In the oil and gas industry, the stakes are incredibly high. The fluids being transported are often flammable, toxic, or under extreme pressure. Here, precise flow control is not just about efficiency; it is a matter of life and death. A sudden surge in gas pressure or an uncontrolled flow of liquids can lead to catastrophic equipment failure or environmental disasters. This is why oil and gas companies invest heavily in top-tier valve solutions.

Precise flow ensures that chemical reactions happen at the right speed and that pipelines are not over-pressurized. In natural gas processing, for instance, control valves must maintain exact pressures to separate impurities effectively. Even a small deviation can ruin the product quality or damage downstream equipment. Advanced control strategies are employed to monitor these valves in real-time, ensuring they react instantly to any process conditions that change.

Furthermore, precise control translates directly to profitability. In metering applications, where oil and gas are sold by volume, the accuracy of the flow determines revenue. A valve that leaks or fails to hold a stable flow rate effectively gives away product for free. Reliability in this sector is non-negotiable. The valves serve as critical components that safeguard both the personnel and the profit margin.

What are the Different Types of Flow Control Valves Available?

There is no single valve for the job; the variety is immense because every application has unique needs. To optimize a system, you must choose the right tool. Here is a breakdown of common types of flow control valves:

| Valve Type | Primary Function | Best Use Case |

|---|---|---|

| Globe Valves | Throttling and regulating flow | Precise flow regulation in cooling water or fuel systems. |

| Gate Valves | On/Off control | Isolation of a pipeline; not good for throttling. |

| Ball Valves | Quick On/Off control | Tight shut-off for gas and liquid lines. |

| Diaphragm Valves | Sanitary/Corrosive handling | Pharmaceutical or chemical applications where the fluid must be isolated from valve mechanics. |

| Check Valves | Prevent backflow | Ensuring fluid flows only in one direction, protecting pumps. |

| Needle Valves | Very fine flow control | Instrumentation and precise calibration tasks. |

Gate valves are the workhorses for shutting off flow completely, while globe valves are the masters of regulation. Ball valves are prized for their durability and ability to provide a tight seal, which is crucial in gas applications. Check valves, such as our Double Pilot Operated Check Valves, are passive safety devices that prevent the flow from reversing, which could damage pumps or drain reservoirs.

Understanding the specific characteristics of these valve technologies is the first step in valve selection. You wouldn't use a gate valve if you needed precise flow control, and you wouldn't use a needle valve to stop a massive pipe. Matching the valve type to the process requirements is the key to optimal efficiency.

How Does Automating Valve Control Enhance Safety and Reliability?

Manual valve operation is slow, labor-intensive, and prone to human error. To enhance safety and reliability, modern industries automate their valve control. By integrating valves into automated systems, companies remove the operator from hazardous environments. Instead of sending a person to turn a handwheel on a hot steam pipe or a high-pressure gas line, a signal is sent from a control room, and an actuator does the work.

Automation allows for reaction times that no human can match. If a sensor detects a dangerous pressure spike, the control system can instantly shut down the relevant control valve to prevent an explosion. This automated control is the backbone of modern safety protocols. It ensures that the process control remains within safe limits 24/7, without fatigue or distraction.

Moreover, automated systems provide consistency. A computer will open a valve to exactly 42% every single time, whereas a human operator might hit 40% one time and 45% the next. This consistency stabilizes the industrial process, leading to predictable product quality and less waste. Reliability increases because the actuator applies smooth, controlled force to the valve, reducing physical wear and tear compared to manual operation.

Can Advanced Control Algorithms Optimize Performance and Efficiency?

Hardware is only half the equation. The software—the control algorithms—is what truly unlocks the potential of a flow control valve. Advanced control strategies, such as PID (Proportional-Integral-Derivative) loops, allow the system to predict and correct errors in flow rate or pressure before they become problems. By constantly analyzing the difference between the desired setpoint and the actual process conditions, the algorithm adjusts the valve position with incredible precision.

We are seeing a move towards adaptive control and predictive maintenance. Smart valves equipped with sensors can "feel" the flow. They can detect if the valve is sticking or if the seat is wearing out. The control system can then adjust its signals to compensate for this wear, maintaining optimal performance even as the hardware ages. This capability to optimize performance dynamically is a game-changer.

These control strategies also contribute to operational efficiency by minimizing "hunting." Hunting occurs when a valve constantly opens and closes, trying to find the right position. This wastes energy and wears out the components. Advanced control smooths out these movements, ensuring the valve finds the steady state quickly. This stable operation reduces stress on the piping systems and extends the life of the high-quality valves.

How Do You Go About Selecting the Right Valve for the Job?

Selecting the right valve can feel overwhelming given the choices. However, focusing on a few key factors can simplify the valve selection process. First, define the fluid. Is it a corrosive liquid, a thick oil, or a high-pressure gas? The material of the valve body and seals must be compatible with the media to prevent leaks and failure.

Next, consider the flow rate and pressure. You need a valve that can handle the maximum pressure of the system without bursting, but it also needs to be sized correctly for the flow. A control valve that is too large will be twitchy and hard to control at low flows. A valve that is too small will create a massive pressure drop and starve the system.

Finally, think about the control system. Do you need simple on/off control, or do you need precision flow regulation? This determines if you need a simple ball valve or a sophisticated Flow Regulator Valve. Don't forget the environment. Will the valve be exposed to extreme heat or cold? Consulting with a specialist supplier helps ensure you get the right flow control valve that will optimize your specific industrial operations.

What Role Do Actuators Play in Automated Systems?

The actuator is the muscle of the control valve. While the valve body controls the fluid, the actuator controls the valve body. In automated systems, the actuator receives a signal (electric, pneumatic, or hydraulic) from the controller and converts it into mechanical motion to change the valve position. Without a reliable actuator, even the best valve is useless in an automated setup.

There are different types of actuators for different needs. Pneumatic actuators are common in industrial applications because they are fast and inherently safe (they don't spark). Electric actuators offer incredibly precise control and position feedback, making them ideal for complex process control loops. Hydraulic actuators provide immense force, necessary for moving large gate valves or ball valves in high-pressure pipelines.

The pairing of the valve and actuator is critical. The actuator must have enough torque or thrust to close the valve tightly against the pressure of the fluid, but not so much that it damages the valve stem. A well-matched set ensures smooth valve control, allowing the system to regulate the flow effectively and respond instantly to command signals.

How Does Valve Performance Impact Energy Consumption?

In today's market, energy consumption is a major concern for cost and environmental reasons. Surprisingly, valve performance plays a huge role in a plant's energy footprint. A poorly sized or functioning control valve can cause significant energy loss. For example, if a valve creates an excessive pressure drop, the system's pumps must work harder to push the fluid through, consuming more electricity.

High-quality valves designed for optimal efficiency minimize this resistance. They allow the fluid flow to pass with less friction. Furthermore, precise control allows the system to run closer to its limits without exceeding them. This means you don't have to "over-pump" just to be safe. You can pump exactly what is needed, and the valve will manage the rest.

Leaking valves are another source of wasted energy. A leaking steam valve, for instance, is literally venting money into the air. Predictive maintenance, enabled by smart valve technologies, helps identify these leaks early so they can be fixed. By focusing on valve performance, industries can significantly reduce energy consumption and improve their bottom line while boosting operational efficiency.

What Future Valve Technologies Will Revolutionize Industrial Operations?

The future of valve control is digital. We are moving towards "smart valves" that are fully integrated into the Industrial Internet of Things (IIoT). These valve technologies do more than just open and close; they communicate. They transmit data about flow rate, temperature, pressure, and their own mechanical health back to the central control system.

This connectivity allows for predictive maintenance on a new level. Instead of fixing a valve when it breaks (reactive) or on a schedule (preventative), you fix it exactly when it needs it. The valve might tell you, "My seal friction is increasing, please schedule maintenance in two weeks." This drastically reduces downtime and increases reliability.

Additionally, we are seeing advancements in materials that allow valves to withstand harsher process conditions, deeper underwater environments for oil and gas, and more corrosive chemicals. The integration of AI into control algorithms will eventually allow valves to self-tune, finding the perfect valve position to optimize the process without human intervention. The future of industrial operations is smart, connected, and driven by advanced valve solutions.

Key Takeaways

- The Heart of the System: The control valve is the essential physical link between your control system and your industrial process.

- Precision Matters: Precise flow control is critical for safety, quality, and profitability, especially in volatile sectors like oil and gas.

- Variety is Key: From gate valves to ball valves and specialized High Pressure 3 Ways Diverter Valves, selecting the valve type must be based on the specific fluid and function.

- Automation Equals Safety: Integrating valves into automated systems removes humans from danger and ensures consistent, reliable valve control.

- Efficiency Savings: Proper valve selection and maintenance can significantly reduce energy consumption by minimizing pressure loss and preventing leaks.

- Future Proof: Investing in high-quality, smart valve technologies now prepares your facility for the data-driven future of process control.

By focusing on these elements, you can ensure that your facility isn't just running, but is truly optimized for success.