The Importance of Regular Valve Maintenance and Pressure Relief Valve Calibration

2025-12-18As a factory owner who has managed hydraulic production lines for over ten years, I have seen the good, the bad, and the ugly of industrial machinery. I have walked into facilities where the hum of production is music to the ears, and I have seen others silent due to catastrophic equipment failure. Often, the difference between these two scenarios comes down to one small, often overlooked component: the valve.

For procurement professionals and business owners like you, keeping operations running smoothly is the top priority. You understand that downtime costs money—not just in lost production, but in the scramble to fix things. Today, I want to talk about a critical aspect of facility management that is often underestimated: valve maintenance. Specifically, we will dive into why the calibration of your pressure relief valve inventory is not just a technical suggestion, but a mandatory practice to ensure compliance and safety.

Why is Regular Valve Maintenance Essential for Industrial Operations?

In any industrial setting, from oil and gas refineries to construction sites using excavators, the valve is the gatekeeper of energy. It controls the flow, pressure, and direction of fluids. However, like any mechanical device, a valve is subject to degradation. Regular valve maintenance is essential to keep these components functioning correctly. Without it, you are essentially gambling with the reliability of your entire system.

Regular maintenance involves more than just wiping off the dirt. It requires a systematic inspection of the valve body, the actuator, and the internal components. We look for signs of wear, loose connections, and potential leaks. By catching these issues early, we can perform a minor repair instead of a major overhaul. This proactive approach helps to extend the lifespan of pressure equipment and keeps your industrial operations running without interruption.

Imagine a scenario where a critical control valve gets stuck due to lack of lubrication. The entire production line halts. The cost of that downtime far exceeds the cost of a routine maintenance check. By implementing regular valve checks, you ensure that valves are always ready to perform their duty, safeguarding your investment and your profit margins.

What is the Critical Role of a Pressure Relief Valve in Safety?

Among all the valve types in a system, the pressure relief valve (PRV) is arguably the most important for safety. Its job is simple but vital: it opens when the pressure levels in a system become too high. Think of it as a safety fuse. If a pump fails or a blockage occurs, the pressure relief valve allows the excess pressure to escape, preventing pressure vessels or pipes from bursting.

The relief valve is to protect the system from overpressure events that could lead to catastrophic failure. However, a PRV is a dormant safety device. Unlike a flow control valve that moves constantly, a pressure relief valve might sit closed for years, waiting for that one emergency moment. If it has seized shut due to lack of valve maintenance, it won't open when you need it to.

This is why pressure relief valves to ensure safety must be treated with care. They are the last line of defense against safety hazards that could injure personnel or destroy property. Our Direct Acting Relief Valves are designed to react instantly, but even high-quality valves need care to function when it counts.

How Do Corrosion and Wear Affect Valve Performance?

Industrial processes are often harsh. Valves operate in demanding environments where they are exposed to high temperatures, abrasive particles, and corrosive fluids. Over time, corrosion eats away at the metal of the valve body and internal parts. This can weaken the structure and lead to a dangerous leak.

Wear and tear is another enemy. Every time a valve opens and closes, friction occurs. The seal surfaces can become scratched or pitted. Once a seal is compromised, the valve can no longer hold pressure effectively. In a pressure relief valve, corrosion or debris can affect the spring mechanism or cause the disc to stick to the seat. This means the valve might open too late (allowing dangerous pressure) or too early (causing system inefficiency).

Regular inspection allows a technician to spot corrosion before it causes failure. Cleaning the internal components and replacing a worn seal are simple steps that restore valve performance. Ignoring these physical signs of degradation is a fast track to premature failure and significant operational headaches.

What Does the Calibration Process Entail for Pressure Relief Valves?

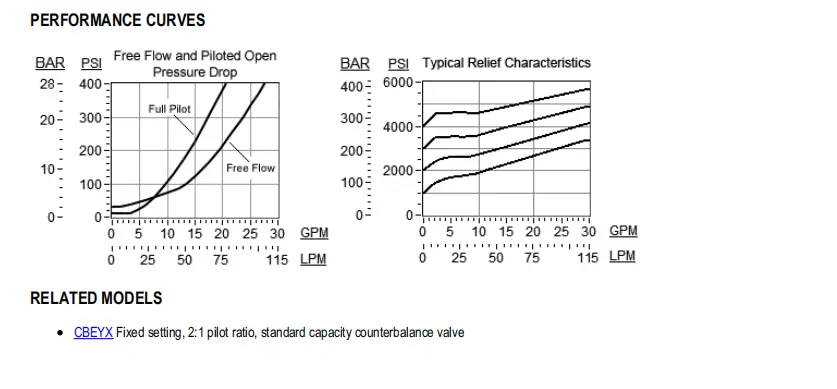

Calibration is the process of verifying and adjusting the valve to ensure it opens at the exact required pressure. For a pressure relief valve, this is known as the "set pressure." The calibration process typically happens on a test bench, isolated from the main system.

A qualified technician will mount the valve on the rig and slowly increase the pressure using a calibrated pressure gauge. They watch closely to see exactly when the valve opens (often indicated by a "pop" or a continuous hiss). If the valve opens at 100 bar, but your system safety limit is 90 bar, the valve needs adjustment. The technician adjusts the spring tension until the valve opens at the precise pressure required.

Proper calibration also checks for seat tightness—ensuring the valve closes back up tightly after the pressure drops. This "reseat pressure" is crucial to prevent leakage during normal operation. Regular calibration of pressure relief valves ensures that the mechanical reality of the valve matches the safety design of your system.

Why is Calibration Essential to Ensure Compliance with Industry Standards?

In industries like manufacturing and oil and gas, following the rules isn't optional. Compliance with industry standards (such as ASME, API, or ISO) is a regulatory requirement. These standards dictate that safety devices like pressure relief valves must be maintained and tested regularly.

Calibration is essential because it provides proof. When an auditor checks your facility, they will ask for maintenance records. A certificate of calibration proves that your valves were tested against a known standard and were functioning correctly. Failing to ensure compliance can lead to heavy fines, legal issues, or even a forced shutdown of your operations.

Moreover, compliance with industry regulations protects your insurance coverage. If an accident happens and investigation reveals that your valves were neglected, insurance companies may refuse to pay. By investing in regular calibration, you ensure compliance and build a layer of legal and financial protection for your business.

How Can a Proactive Maintenance Schedule Reduce Downtime?

Many companies operate on a "run-to-failure" capability. They only fix a valve when it breaks. This is a costly strategy. A proactive maintenance schedule shifts the focus to preventing problems. By scheduling regular valve maintenance, you can plan downtime during slow production periods rather than being surprised by a breakdown in the middle of a rush order.

A good maintenance schedule tracks the history of each valve. It tells you when the last inspection was, when the next calibration is due, and what repairs were done. This data allows you to predict when a valve reaches the end of its useful lifespan and plan for a replacement before it fails.

This strategy significantly reduces downtime. Instead of scrambling to find a spare part while your crew stands idle, you have the part ready. Maintenance helps optimize your operational efficiency. For instance, checking your End of Stroke Valve regularly ensures that your automated machinery cycles correctly every time, preventing production jams.

What Are the Risks of Ignoring Pressure Gauge and Valve Calibration?

You cannot calibrate a valve without a trusted reference. This is where the pressure gauge comes in. If the pressure gauge on your test bench or your machine is inaccurate, your calibration is worthless. Inaccurate pressure readings can lead you to set a relief valve dangerously high or inefficiently low.

Ignoring calibration creates a false sense of security. You might think your system is protected at 2000 PSI because the valve is stamped with that number. But if the spring has weakened over years of use, it might open at 1500 PSI, causing constant interruptions. Or worse, corrosion might make it stick until 3000 PSI, risking an explosion.

These are major safety hazards. An uncalibrated valve is an unpredictable variable in your industrial processes. It poses a risk to the flow of fluids and gases, the equipment, and the workers. Regular calibration eliminates this uncertainty, ensuring that pressure readings and valve actions are synchronized and safe.

Repair vs. Replacement: Making the Right Decision for Your Valves

During a maintenance cycle, you will often face a choice: repair the existing valve or buy a new one? This decision depends on several factors, including the cost of the repair kit, the age of the valve, and the criticality of its role.

For high-quality, expensive industrial valves, a repair (replacing seals, lapping seats, polishing stems) is often the most cost-effective choice. It restores the valve to "like-new" condition for a fraction of the price. However, if the valve body shows deep corrosion or if the internal wear is extensive, replacement is the safer option.

Sometimes, upgrading is better than repairing. Newer valve types, like our efficient Relief Valve-Cartridge Type, are easier to swap out and maintain than older, bulky models. Making the smart choice between repair and replacement helps manage maintenance costs while maintaining reliability.

How Do We Ensure Compliance Through Documentation and Testing?

Documentation is the backbone of compliance. Every time a valve is inspected, repaired, or calibrated, it must be recorded. A robust documentation system should include:

- The valve's unique ID tag.

- The date of service.

- The "As-Found" condition (did it pass or fail initially?).

- The work performed (cleaning, parts replaced).

- The "As-Left" condition (final calibration results).

- The name of the technician.

This paper trail proves that you are taking care of your equipment. It is what inspectors look for to verify compliance with regulations. Furthermore, this data helps you analyze trends. If a specific valve fails calibration every six months, you know you have a systematic issue—perhaps the operating conditions are too harsh for that specific valve type.

Ensures that the valves in your facility are not just working, but are proven to be working. This transparency builds trust with clients and regulatory bodies alike.

Summary: The Pillars of Valve Safety

To summarize, maintaining your valve inventory is not a burden; it is a strategic investment. Here are the key takeaways to remember:

- Safety First: The pressure relief valve is your primary defense against overpressure and catastrophic failure.

- Prevent Downtime: Regular valve maintenance identifies potential issues before they stop production.

- Fight Degradation: Routine cleaning and inspection combat corrosion and wear and tear.

- Accuracy Matters: Calibration ensures your valves open at the precise pressure required for safety and efficiency.

- Stay Legal: Proper maintenance and documentation are required to ensure compliance with industry standards.

- Save Money: Proactive care reduces expensive emergency repairs and extends the lifespan of your assets.

By prioritizing regular maintenance and calibration, you ensure that your industrial operations remain safe, compliant, and profitable. Whether you are using a simple check valve or a complex Single in Line Counterbalance Valve, treating your valves with respect ensures they will serve you well for years to come.