Mastering the Hydraulic Valve: Maximizing Pressure and Performance in Your Hydraulic System

2025-12-11For over ten years, I have been running a factory in China with seven production lines dedicated to one thing: manufacturing the best hydraulic components possible. I have shaken hands with buyers from all over the world, but I work most often with professionals like Mark Thompson from the USA. I know that for someone like Mark—a decisive business owner who values quality but needs a competitive edge—dealing with suppliers can sometimes be a headache. You worry about delayed shipments, confusing communication, or receiving a valve that doesn't meet the specs on the paper.

I am writing this to clear the air. A hydraulic system is only as good as its smallest components, and usually, that component is a hydraulic valve. Whether you are building excavators, cranes, or industrial presses, understanding how these valves work, how to choose them, and how to maintain them is the secret to performance and efficiency. In this guide, we will walk through the intricacies of hydraulic control, exploring everything from the basic relief valve to advanced flow control valves. My goal is to give you the knowledge to make smart, safe purchasing decisions that keep your business profitable.

What is the Heart of Hydraulics? Understanding the Hydraulic Valve

If the pump is the heart of a hydraulic system, creating flow, then the valve is the brain and the muscle combined. It tells the hydraulic fluid where to go, when to stop, and how hard to push. Without a hydraulic valve, a system would just be a loop of fluid moving around without doing any useful work. The valve transforms raw power into controlled motion.

In simple terms, a valve opens or closes a path. But in hydraulics, it does much more. It manages the pressure that builds up inside the cylinders. It controls the flow rate, which decides how fast a machine moves. It also determines the direction the actuator moves—left, right, up, or down. Valves play a crucial role in every single cycle of the machine.

For a buyer, it is important to know that not all valves are created equal. The valve body must be machined with incredible precision. The internal spool or poppet needs to fit perfectly to prevent internal leakage, which robs the system of power. When I walk my production line, I am constantly checking these tolerances. A high-quality valve ensures reliability and consistent system performance, while a cheap one leads to jerky movements and downtime.

How Do Different Types of Hydraulic Valves Control the Flow?

There are thousands of valves out there, but they generally fall into three main categories based on what they control: direction, pressure, and flow. Understanding these types of hydraulic valves is step one in selecting a hydraulic solution.

Directional Control Valves: These are the traffic cops. They change the path of the fluid flow. A simple check valve allows fluid to move one way but blocks it from coming back. More complex spool valves can shift to send fluid to one side of a cylinder to extend it, and then shift again to retract it.

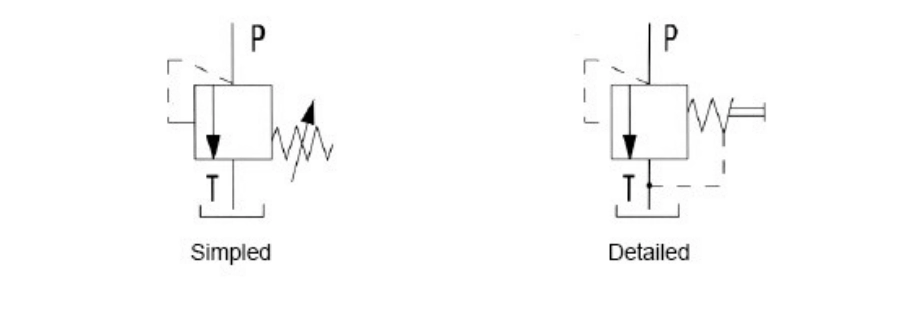

Pressure Control Valves: These valves manage the force. They ensure the system pressure doesn't get too high (safety) or maintain a specific pressure in one part of the circuit. A relief valve is the most common example here.

Flow Control Valves: These manage speed. By restricting the opening the fluid passes through, they control the flow rate. If you want your crane arm to lift slowly and smoothly, you need a good flow control valve.

Valves are designed to work together. A typical circuit might use a directional valve to start the movement, a flow control valve to set the speed, and a pressure valve to limit the force. Each valve type has a specific job to do to ensure safe and efficient operation.

Why is the Relief Valve Critical for System Safety?

Imagine a hydraulic pump that keeps pushing fluid into a cylinder that has hit a hard stop. The fluid has nowhere to go. Without a safety mechanism, the pressure would rise instantly until a hose bursts or the pump explodes. This is where the relief valve steps in. It is the guardian of the hydraulic system.

The relief valve is a normally closed valve. It sits quietly in the system until the pressure reaches a preset limit. When the pressure exceeds this limit—let's say 3000 PSI—the valve pops open. It diverts the excessive pressure and fluid back to the tank. This limits the maximum force the system can generate and protects the components in hydraulic machines from damage.

We manufacture Direct Acting Relief Valves that are designed to react in milliseconds. This fast response time is critical to prevent pressure peaks that can damage sensitive seals and sensors. In many ways, the relief valve is the most important investment you make for safety hazards prevention. It ensures the machinery operates within its design limits, preventing catastrophic failures.

How Do Flow Control Valves Regulate Speed and Movement?

Speed control is essential for precision. Whether you are pouring molten metal or placing a delicate component on an assembly line, you cannot have the actuator slamming around. Flow control valves act like a dimmer switch for a light bulb, but for hydraulic fluid.

By adjusting the size of the orifice inside the valve, we create a pressure drop. This resistance slows down the flow of hydraulic fluid reaching the actuator. Less flow means slower movement. However, it is not just about making things slow. It is about consistency. Advanced flow control valves, like our Flow Regulator Valves, are pressure-compensated. This means that even if the load on the cylinder changes (requiring more pressure), the valve adjusts to keep the speed constant.

This precise control allows operators to work safely and efficiently. It reduces mechanical shock to the machine structure, which extends longevity. When selecting a hydraulic component for speed, always look at the flow curves to ensure the valve offers the smooth regulation you need.

What is the Role of Servo Valves in High-Precision Applications?

For standard machinery, standard valves are great. But what about an aerospace simulator or a high-speed plastic injection molding machine? These require precision and efficiency beyond what a normal spool valve can offer. Enter the servo valves.

Servo valves are the Formula 1 cars of the hydraulic valve world. They use an electrical signal to control the valve spool with incredible accuracy. Often, they use a small pilot valve (a torque motor) to move the main spool. They provide continuous, infinite control over both flow and pressure. This allows for complex motion profiles and rapid changes in direction.

The downside? They are expensive and sensitive to contamination. A tiny particle of dirt can jam a servo valve because the clearances are so tight. However, for applications where valve control needs to be exact to the micron, there is no substitute. They represent the pinnacle of hydraulic technology. While we focus on robust industrial valves, understanding servo technology helps in appreciating the spectrum of valves in hydraulic systems.

How Does Valve Control Affect Overall System Efficiency?

Energy efficiency is a hot topic. A well-designed hydraulic system saves fuel and electricity. The valve plays a huge part in this. Every time fluid passes through a valve, there is some friction, which creates heat. This is known as pressure drop. A poorly designed or undersized valve creates a lot of heat, wasting energy.

Furthermore, internal leakage is an efficiency killer. In spool valves, a tiny amount of fluid naturally leaks past the spool lands. This is normal for lubrication. However, if the valve is worn or cheaply made with poor tolerances, this leakage increases. The pump has to work harder just to maintain pressure, burning more energy.

Using the right valve control strategies, such as using "load-sensing" valves, ensures the pump only produces the flow and pressure actually needed for the work. This dramatically improves overall system efficiency. High-quality valves provide a tight seal and smooth flow paths, minimizing losses. This is why valves are essential for running a green and cost-effective operation.

Selecting a Hydraulic Valve: What Specifications Matter Most?

When you look at a catalog or talk to a supplier like me, you will see a lot of numbers. Which ones matter? To ensure optimal system performance, you need to match the valve to the application.

- Pressure Rating: Can the valve handle the maximum system pressure? Never underscore this. If your system runs at 3000 PSI, get a valve rated for at least that, preferably more.

- Flow Capacity: Can the valve handle the required flow rate without creating excessive pressure drop? An undersized valve will choke the system and cause overheating.

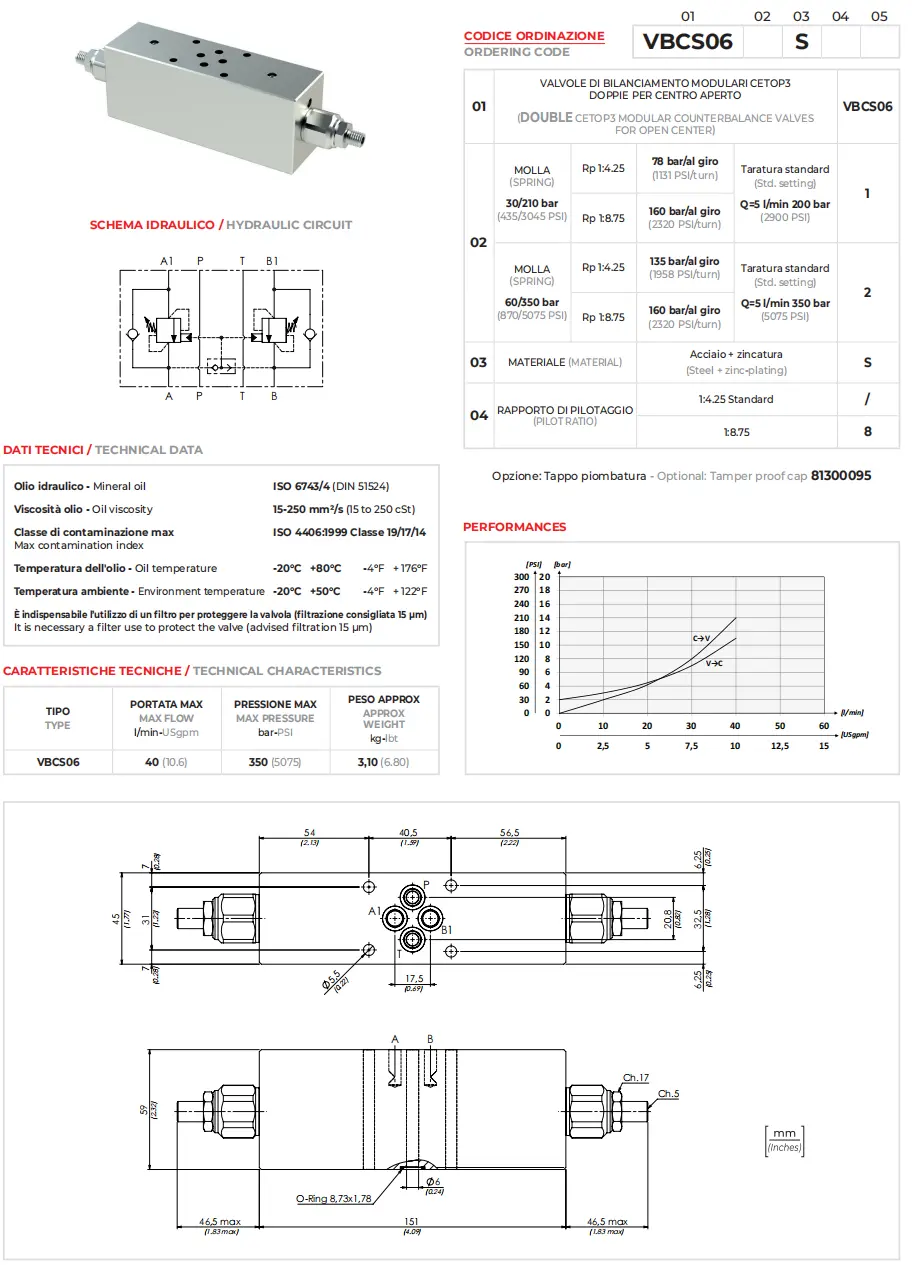

- Mounting Style: Is it an in-line valve, a subplate mount, or a cartridge valve? This affects how you build your manifold.

- Actuation Method: Do you need a manual lever, an electric solenoid, or hydraulic pilot control to control the flow?

- Material: Is the valve body steel, iron, or aluminum? This affects durability and weight.

Taking the time to check these specs prevents downtime later. It ensures the valve is capable of handling the job. Our team often helps clients walk through these choices to find the perfect Double Pilot Operated Check Valves or other components for their specific machines.

Can Standard Valves Survive Harsh Environments?

My customers in the USA often use machinery in tough places—mines, construction sites, and offshore rigs. These are harsh environments. A standard valve might look tough, but salt spray, extreme heat, or abrasive dust can destroy it quickly.

Corrosion is the primary enemy. A steel valve body can rust, causing the handle to seize or the coil to fail. For these environments, we recommend valves with special plating (like zinc-nickel) or stainless steel components. Extreme temperatures also play a role. In very cold climates, standard seals become brittle and crack. In very hot climates, the oil gets thin, and leakage increases.

To ensure reliability, you must specify the operating conditions. We use specific seal materials like Viton for high heat or special low-temp nitrile for the cold. We also offer High Pressure 3 Ways Diverter Valves built with robust steel bodies to withstand physical abuse. Protecting the valve from the outside is just as important as what happens inside.

Top Tips for Hydraulic Valve Maintenance and Operation

Even the best valve in the world will fail if abused. To get the maximum longevity out of your investment, follow these tips for hydraulic maintenance.

- Fight Contamination: This is rule number one. Dirt, metal shavings, and water are death to hydraulic valves. They score the spool, jam the poppet, and ruin the seal. Always use high-quality filters and change the hydraulic fluid regularly.

- Monitor Temperature: excessive heat breaks down the oil and hardens the seals. If your valve is too hot to touch, there is a problem.

- Check for Leaks: A small drip today is a blown hose tomorrow. regularly inspect the valve connections and tighten them if needed.

- Listen to the System: A whining pump or a banging valve (water hammer) indicates issues with pressure control or aeration.

Regular maintenance is cheaper than repairs. Keeping the fluid clean and the system cool ensures the performance of hydraulic systems remains high for years.

Best Practices for Troubleshooting Valve Issues

When a machine stops, panic sets in. Downtime costs money. Troubleshooting a hydraulic valve requires a logical approach.

- Check the Coil: For solenoid valves, is the coil getting power? Is it magnetized? A burnt coil is a common and easy fix.

- Check the Pressure: Use a gauge. Is the pump producing pressure? Is the relief valve set too low, dumping all the flow back to the tank?

- Check for Mechanical Jamming: If the valve has a manual override, try pushing it. If it feels stuck, there might be debris inside the valve body.

- Inspect Seals: If the cylinder drifts or lacks power, the seal inside the valve or the cylinder might be bypassed.

By systematically checking these points, you can often find the issue quickly. Understanding the operation of hydraulic systems helps you isolate whether the problem is the pump, the valve, or the actuator.

Key Takeaways

- The Valve is Vital: The valve is the control center of your hydraulic system, managing direction, pressure, and flow.

- Types Matter: Know the difference between pressure control valves, flow control valves, and directional control valves to choose the right tool for the job.

- Safety First: A relief valve is non-negotiable. It protects your expensive machinery from excessive pressure.

- Efficiency = Profit: A properly sized valve reduces pressure drop and energy consumption, saving you money on fuel and electricity.

- Cleanliness is King: Contamination causes the majority of valve failures. Keep your oil clean to protect the precise control mechanisms.

- Right Material for the Job: In harsh environments, standard valves will fail. Upgrade materials and seals to ensure reliability and longevity.

I hope this guide has shed some light on the critical role of valves in hydraulic equipment. As a manufacturer, I take pride in every valve that leaves my factory, knowing it will power the machines that build our world. If you have questions or need a partner who values quality as much as you do, I am always here to help.