A Practical Guide to Troubleshooting Common Pilot-Operated Check Valve Problems

2025-10-29In my years of manufacturing hydraulic valves, I've learned that even the most reliable components can face challenges in the field. One valve that often comes up in technical discussions is the pilot-operated check valve. It's a fantastic device, essential for safely holding loads, but when a cylinder starts to drift or a function won't operate, this valve is often a prime suspect. This article is for the procurement officers, maintenance managers, and equipment owners like Mark in the USA who need a clear, straightforward guide to understanding and troubleshooting these critical components. We'll demystify common pilot-operated check valve issues, helping you diagnose problems quickly and get your machinery back to optimal performance with minimal downtime.

What is a Pilot-Operated Check Valve and How Does It Work?

Before we dive into troubleshooting, let's quickly recap what this special valve does. A standard check valve is a simple one-way street for hydraulic fluid; it allows free flow in one direction and completely blocks reverse flow. This is great for many applications, but what if you need to allow that fluid to flow back on command? That's where the "pilot-operated" part comes in. A pilot operated check valve adds a clever trick: it can be "unlocked" by a separate hydraulic signal.

Imagine a door with a standard lock. You can always push it open from one side (that's the free flow direction). From the other side, it's locked. The pilot operated check adds a second, special keyhole. When you apply pressure to this keyhole (the pilot port), it mechanically pushes the lock open, allowing the door to swing freely in both directions. In our hydraulic valve, this "pilot pressure" is a small amount of hydraulic fluid delivered through a separate pilot line. This signal pushes on a small piston inside the valve, which in turn lifts the main check poppet off its seat, enabling controlled release of the trapped fluid and allowing reverse flow. This dual functionality makes the pilot operated check valve pilot operated system perfect for load-holding applications.

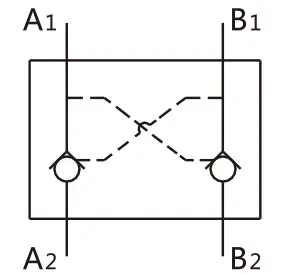

This ability to lock a cylinder in position and then release it on command is why this type of valve is so common. It's often called a holding valve. Without it, the weight on a crane or the arm of an excavator could cause the cylinder to slowly creep or drift down. The check pilot function provides a secure, positive lock. Our Double Pilot Operated Check Valves are specifically designed for this kind of reliable load-holding performance, a feature that is non-negotiable for safe machinery operation.

Why is My Hydraulic Cylinder Drifting? Investigating Valve Leakage

This is by far the most common complaint related to a pilot-operated check valve: a hydraulic cylinder that won't hold its position and slowly drifts or creeps down. The cause is almost always internal leakage past the poppet seat of the check valve. When the valve is closed, the poppet is supposed to create a perfect, leak-free seal. If even a tiny amount of hydraulic fluid can get past this seal, the cylinder will lose its holding power.

So, what causes this leak? The common causes are:

- Contamination: A single speck of dirt, a metal shaving, or a piece of a degraded seal can get trapped between the poppet and the seat. This prevents the valve from closing completely, creating a small path for fluid to leak through. This is the number one enemy of all hydraulics.

- Scratched Seat or Poppet: If abrasive particles have been flowing through the hydraulic system, they can scratch or score the finely machined sealing surfaces of the poppet and seat. These scratches act like tiny channels, allowing for persistent internal leakage.

- Worn or Damaged Seals: While the primary seal is metal-to-metal, many valve configurations use soft seals as well. Over time, these can degrade, become brittle, or get damaged, compromising the seal.

- Corrosion: In systems with water contamination or incompatible hydraulic fluid, corrosion can pit the sealing surfaces, making a positive seal impossible.

Troubleshooting this issue involves confirming the leak is from the valve itself. If the valve is leaking internally, it will almost always need to be replaced. There's no simple fix for a physically damaged sealing surface inside a valve.

My Valve Won't Open for Reverse Flow. What are the Common Problems?

The second major issue is the opposite of the first: the cylinder is locked in position and you can't get it to move because the pilot operated check valve won't open to allow reverse flow. The check valve portion is working, but the pilot-operated unlocking mechanism is failing. When you encounter this problem, your troubleshooting should focus on the pilot signal.

The primary suspect is a lack of sufficient pilot pressure at the pilot port. You need to ask: is the pilot signal being generated, and is it reaching the valve? Here’s a checklist:

- Check the Pilot Source: The pilot pressure usually comes from the other side of the system's main directional control valve. Ensure this directional valve is shifting fully to its intended position. A faulty solenoid or a sticking spool in the directional control valve can prevent it from sending the necessary pressure.

- Inspect the Pilot Line: The hydraulic lines that carry the pilot signal are often small. Check for blockages, kinks, or leaks in the pilot line. A small piece of debris can easily clog this line.

- Verify Pressure Levels: The valve has something called a pilot ratio. This ratio (e.g., 3:1 or 5:1) tells you how much the pilot pressure is amplified to unseat the main poppet. You need to ensure the pilot pressure being supplied is high enough to overcome both the load-induced pressure in the cylinder and the valve's spring force, according to this ratio. If the pressure is too low, the valve simply won't open.

In some cases, the valve itself could be at fault. The internal pilot piston could be stuck due to contamination or mechanical failure. However, it's always best to rule out problems with the pilot signal first, as they are often easier and cheaper to fix.

What Causes a Pilot-Operated Check Valve to Get Stuck Open?

While less common, a pilot operated check valve getting stuck in the open position is a serious safety concern. If this happens in a load-holding application, the load could drop uncontrollably as soon as the directional valve is centered. This problem essentially turns the check valve into an open line, offering no resistance to reverse flow.

The primary cause for a valve sticking open is severe contamination. A large piece of debris, like a sliver of metal from a failing gear pump or a chunk of a failed hose, can become physically wedged between the poppet and the seat, forcing the valve to stay open. This prevents the spring from being able to reseat the poppet when the pilot pressure is removed.

Another potential cause is mechanical failure within the valve itself. The return spring that is supposed to push the poppet closed could break, or the pilot piston could get stuck in the "activated" position. These are signs of a catastrophic valve failure. If you suspect a valve is stuck open, you must immediately and safely shut down the hydraulic system and prevent any movement of the associated cylinder or actuator until the faulty valve can be replaced. Troubleshooting a stuck-open valve is less about diagnosis and more about safe replacement.

How Can I Tell if it's the Valve or the Cylinder That's Failing?

This is a classic troubleshooting question in hydraulics. A drifting cylinder can be caused by a leaking pilot operated check valve OR a leaking piston seal inside the cylinder itself. Both symptoms look identical. Wasting time and money replacing the wrong component is a common frustration. Luckily, there's a relatively simple way to isolate the problem.

Here's a basic diagnostic test:

- Position the Cylinder: Operate the hydraulic circuit to place the cylinder under load (e.g., raise the boom of an excavator slightly off the ground).

- Shut Down Safely: Turn off the engine and safely relieve any stored pressure in the system.

- Identify the Line: Identify the hydraulic hose that connects the port of the pilot operated check valve to the cylinder port that is holding the load.

- Disconnect and Observe: Carefully disconnect this hose at the cylinder port. Place a container underneath to catch any fluid.

- Analyze the Leak:

- If hydraulic fluid continues to leak steadily from the end of the hose (coming from the valve), then the pilot operated check valve is leaking internally and is the faulty component.

- If there is little to no fluid coming from the hose, but fluid is leaking out of the now-open cylinder port, then the piston seals inside the cylinder are leaking, and the cylinder needs to be rebuilt or replaced.

This simple test removes the guesswork and ensures you're targeting the true source of the problem. This is a critical first step before ordering a new valve or cylinder.

What is the Role of the Directional Control Valve in Pilot Operation?

It's impossible to troubleshoot a pilot-operated check valve without considering its partner: the main directional control valve. This valve (often a solenoid valve) is what directs the main flow to the cylinder and, crucially, provides the pilot signal to unlock the check valve. The two valves work as a team, and a failure in the directional valve can easily look like a problem with the check valve.

When you shift a directional control valve to extend a cylinder, it does two things simultaneously. It sends high-volume flow to one side of the cylinder, and it taps into that same pressure line to send a low-volume signal to the pilot port of the check valve on the other side of the cylinder. This unlocks the return path, allowing fluid from the opposite end of the cylinder to flow back to the tank. If the directional valve's spool doesn't shift all the way, it might not open the pilot passage correctly, starving the check valve of its pilot signal.

The type of directional valve also matters. For example, a closed center directional valve blocks all ports in the center position. This is important for systems using these check valves, as it prevents pressure from being trapped in the pilot lines, which could inadvertently hold the check valve open. When troubleshooting, always inspect the directional valve's operation. Is the solenoid energizing? Is the spool moving freely? The problem might be with the Solenoid Valve (Three Ports, Two Positions) and not the check valve at all.

How Can Contamination Lead to Complete Valve Failure?

I've mentioned contamination several times, and I can't overstate its importance. In my factory, we build valves in an extremely clean environment because we know that contamination is the single biggest cause of valve failure in a hydraulic system. These are precision instruments with internal clearances measured in microns. Even particles that are invisible to the naked eye can cause immense damage.

Here’s how contamination wreaks havoc on a pilot operated check valve:

- Abrasive Wear: Hard particles like dirt or metal shavings act like liquid sandpaper, eroding the sharp edges of the poppet and scoring the seat. This wear destroys the valve's ability to seal, leading to cylinder drift.

- Blocking Orifices: The pilot circuit within the valve and in the lines leading to it often has small passages or an orifice to control flow. These are easily blocked by sludge or debris, which can prevent the pilot signal from reaching the pilot piston.

- Sticking Components: Contaminants can build up and cause the pilot piston or even the main poppet to become sticky or completely jammed in one position. This can lead to the valve failing to open or, more dangerously, failing to close.

A well-maintained hydraulic system with proper filtration is the best defense. A clean hydraulic valve is a happy and functioning valve. If you open up a failed valve and see signs of dirty or milky hydraulic fluid, you've likely found the root cause of your common problems.

What Are the First Steps in Troubleshooting a Faulty Hydraulic Valve?

When faced with a hydraulic issue, it's tempting to start replacing parts immediately. However, a systematic approach to troubleshooting will save you time, money, and frustration. Before you grab a wrench, grab a notepad and the machine's schematic.

Here is a logical sequence of troubleshooting tips:

- Observe the Symptoms: Be precise. Is the cylinder drifting down? Is it failing to retract? Does it happen when the fluid is hot or cold? Detailed observations are crucial clues.

- Consult the Schematic: The hydraulic schematic is your roadmap. It shows how the pilot operated check valve is connected to the directional control valve, cylinder, and pilot lines. Understand the intended flow direction and pilot source.

- Check Pressures: If you have the tools, check the main system pressure and, if possible, the pilot pressure at the valve. Are they within the machine's specifications? Low pressure is a common culprit.

- Perform a Visual Inspection: Look for the obvious. Are there any leaking hydraulic lines or fittings? Is a solenoid connector loose? Is the valve body cracked or damaged?

- Isolate the Component: As described earlier, perform tests to confirm whether the problem lies with the valve, the cylinder, or the control valve.

- Inspect the Fluid: Check the condition of the hydraulic fluid. Is it clean and clear, or is it cloudy, dark, or full of particles? The fluid's health is a direct indicator of the system's health.

Only after following these steps should you decide to replace a valve. This methodical process turns guesswork into diagnosis.

How Do Different Pilot-Operated Valve Configurations Change the Approach?

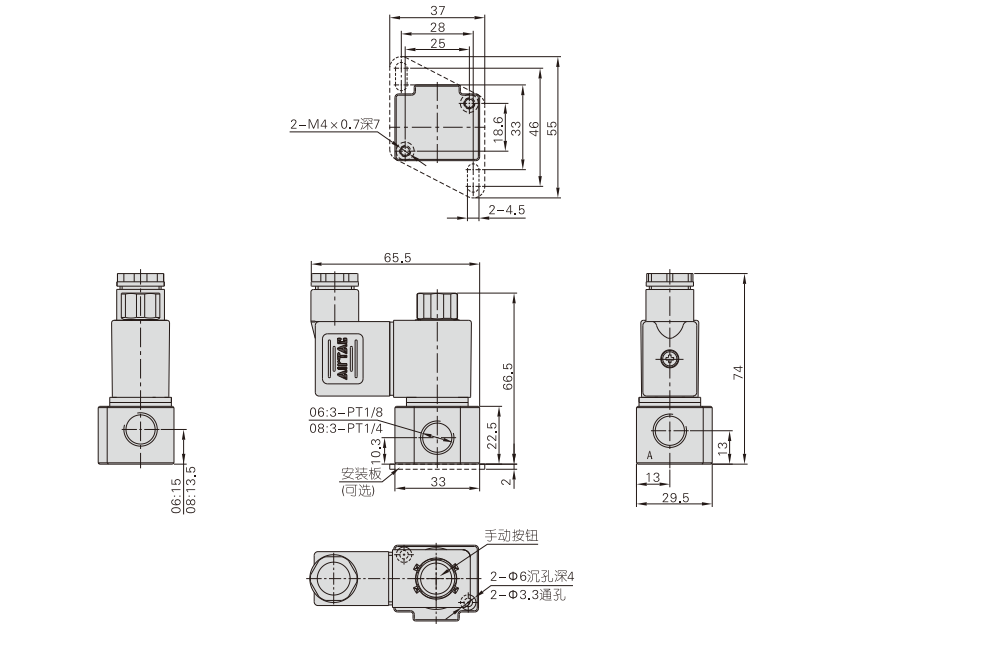

Not all pilot-operated check valve applications are the same. The most common setup involves a double acting cylinder, which requires two pilot-operated check valves, often built into a single valve body called a dual pilot operated check valve. This valve has two check circuits and two pilot ports. When you send pressure to extend the cylinder, that same pressure acts as the pilot signal to unlock the return path from the retract side, and vice-versa.

Troubleshooting a dual pilot operated valve, like our popular F42 Dual Pilot Operating Check Valve, is similar to troubleshooting a single valve, but you have to consider both sides. If the cylinder drifts, is it the check valve on the rod side or the piston side that is leaking? If the cylinder won't extend, is it because the pilot signal isn't unlocking the retract side? The isolation test (disconnecting the hose) becomes even more important here to pinpoint which of the two internal check valves is failing.

Other valve configurations might be mounted on a manifold block, integrated into a cylinder port, or exist as a simple in-line valve. While the internal function is the same, the physical location and connections will change. Always refer to the schematic to understand your specific valve pilot operated check valve setup before you begin troubleshooting.

Are There Preventative Measures to Avoid Common Check Valve Problems?

Absolutely. The best troubleshooting is the kind you never have to do. Preventing valve issues before they start is key to maximizing uptime and ensuring reliable performance. As a manufacturer, I can tell you that a high-quality valve is far more resilient, but even the best components need a healthy system to survive in.

Here are the most effective preventative measures:

- Filtration, Filtration, Filtration: Maintain a strict filter replacement schedule. Clean hydraulic fluid is the single most important factor in the longevity of every component in your hydraulic system, especially a sensitive control valve.

- Use High-Quality Components: Start with a well-made valve from a reputable supplier. As a Professional Hydraulic Relief Valve Supplier and producer of all types of valves, I can attest that better materials, tighter tolerances, and superior quality control result in a valve that is far more resistant to wear and contamination.

- Regular Fluid Analysis: Periodically send a sample of your hydraulic fluid to a lab for analysis. It can reveal hidden problems like high contamination levels, water ingress, or fluid degradation before they cause a major valve failure.

- Routine Inspections: Regularly inspect hoses for wear, check for leaks, and ensure all connections are tight. A small external leak can allow dirt and air to enter the system.

- Proper Operating Temperatures: Avoid overheating the hydraulic system, as high temperatures accelerate fluid breakdown and can damage seals within the valve.

By focusing on system health, you create an environment where your check valves continue to provide the optimal performance they were designed for.

Key Takeaways

Dealing with a faulty pilot-operated check valve can be a challenge, but a systematic approach makes all the difference. Remember these key points to guide your troubleshooting efforts:

- Understand the Function: The valve acts as a one-way check valve until a pilot signal unlocks it to allow reverse flow, making it essential for load-holding.

- Cylinder Drift = Internal Leak: The most common problem, cylinder drift, is almost always caused by internal leakage in the valve due to contamination or wear.

- Failure to Open = Pilot Problem: If the valve won't open for reverse flow, investigate the pilot signal first. Check the pilot line, pressure source, and the main directional control valve.

- Isolate Before You Replace: Always perform a diagnostic test to confirm whether the fault lies in the check valve or the cylinder to avoid replacing the wrong part.

- Contamination is the Enemy: Clean hydraulic fluid and proper filtration are the best preventative measures you can take to avoid nearly all common valve issues.

- Quality Pays Off: Investing in a high-quality, well-manufactured valve from the start is your best defense against premature failure, downtime, and safety risks.