A Comprehensive Guide to Pilot-Operated Check Valves in Hydraulic Systems

2025-09-25In the world of heavy machinery and industrial equipment, control is everything. The ability to lift, hold, and lower massive loads with precision is not magic; it's the result of a well-designed hydraulic system. At the heart of this system are components that ensure safety, reliability, and efficiency. One of the most critical of these is the pilot-operated check valve. This article is your definitive guide to understanding these essential devices. As a manufacturer with over a decade of experience, I, Allen, have seen how a deep understanding of components like this can make or break a project. We'll explore how this specific valve works, why it's different from a standard check valve, and what you, as a procurement officer or system integrator, need to know to make the best purchasing decisions for your hydraulic applications.

What Exactly is a Pilot-Operated Check Valve?

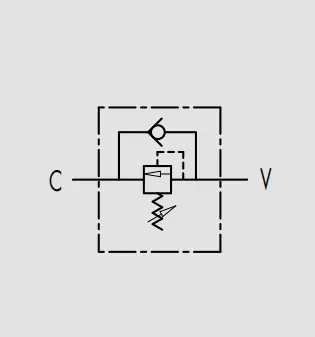

At its core, a pilot-operated check valve is a type of hydraulic valve designed to permit free fluid flow in one direction and block it in the opposite direction, just like a standard check valve. However, it has a unique, crucial feature: it can be "unlocked" or opened by an external pressure signal, known as a pilot pressure. This allows the blocked fluid to flow back through the valve when required. Think of it as a one-way gate that can be remotely opened by a security guard (the pilot signal) to allow traffic to exit.

This dual functionality makes the pilot-operated check valve an indispensable component in hydraulic circuits, especially those requiring load-holding capabilities. The standard check valve simply cannot offer this level of controlled release. This particular valve ensures that a hydraulic actuator, like a cylinder on a forklift, remains locked in position under load, preventing any unwanted drift or movement until the operator intentionally signals for it to move. This precise control is fundamental to the safe and efficient operation of many hydraulic systems. The valve provides a positive lock, making it far more reliable than a directional control valve for holding loads securely.

These valves are essential for safety and performance. The ability to lock fluid in a part of a circuit provides a fail-safe mechanism. If a hose were to break downstream, the check valve would hold the load, preventing a catastrophic failure. Therefore, this specific valve is not just a component for controlling flow; it’s a critical safety device. The design of this valve ensures that even under heavy loads, the system remains stable and predictable, giving operators the confidence they need to perform demanding tasks.

How Does a Standard Check Valve Work Compared to a Pilot-Operated Valve?

To truly appreciate the pilot-operated check valve, you must first understand its simpler cousin, the standard check valve. A standard check valve is one of the simplest types of hydraulic valve. Its purpose is singular: to allow fluid to flow in one direction and completely block it in the reverse direction. It usually contains a ball or poppet held against a seat by a light spring. When fluid pressure in the forward direction is high enough to overcome the spring force, the valve opens. When the flow stops or tries to reverse, the backpressure and the spring snap the valve shut.

A pilot-operated check valve, on the other hand, adds a layer of sophisticated control. While it performs the same basic function of allowing free flow in one direction and blocking reverse flow, it includes a pilot piston. This piston, when activated by a separate pressure signal (the pilot pressure), can physically push the poppet or ball off its seat, overriding its normal checking function. This action opens the valve and allows fluid to flow in the normally blocked reverse direction. This pilot-operated function is what gives the valve its unique ability for precise control over load-holding circuits.

Here is a simple table to illustrate the key differences:

| Feature | Standard Check Valve | Pilot-Operated Check Valve |

|---|---|---|

| Primary Function | Allows flow in one direction only. | Allows flow in one direction; allows reverse flow with a pilot signal. |

| Control Mechanism | Passive (opens with forward pressure). | Active (can be remotely opened for reverse flow). |

| Key Components | Body, poppet/ball, spring. | Body, poppet/ball, spring, pilot piston. |

| Common Use Case | Preventing backflow, circuit isolation. | Load-holding, locking cylinders, safety circuits. |

| Complexity | Very simple. | Moderately complex due to pilot mechanism. |

The distinction is critical. A standard check valve is a simple gatekeeper, while a pilot-operated check valve is an intelligent one that can follow external commands. This makes the latter far more versatile for dynamic hydraulic systems.

Why is a Pilot Signal Crucial for Pilot Valve Operation?

The pilot signal, or pilot pressure, is the "brain" behind the operation of a pilot-operated check valve. Without it, the valve would function identically to a standard check valve, which is useful but lacks the advanced control needed for many applications. The pilot signal is an independent hydraulic pressure line that connects to a port on the valve. This pressure acts on the pilot piston, which is the mechanism that allows for remote control of the valve operation.

When the pilot pressure is applied, it generates enough force on the pilot piston to unseat the main poppet. This is the "unlocking" action. The amount of pilot pressure required depends on the pilot ratio of the valve and the pressure of the trapped fluid it's holding back (the system pressure). For instance, a valve with a 4:1 pilot ratio means that 100 PSI of pilot pressure can generate enough force to open the check mechanism against 400 PSI of trapped system pressure. This mechanical advantage is a key design feature.

The reliability of this pilot signal is paramount. If the pilot line gets blocked or fails to deliver the required pressure, the check valve will not open for reverse flow, and the actuator will remain locked. Conversely, an unintended pilot signal could cause a load to drop unexpectedly. Therefore, the design of the overall hydraulic system must ensure the pilot signal is delivered precisely when needed. This is why high-quality, dependable valves are so important; the pilot valve must respond consistently and reliably every single time to ensure the safe and predictable functioning of the entire machine.

What Are the Key Components of a Hydraulic Pilot Check Valve?

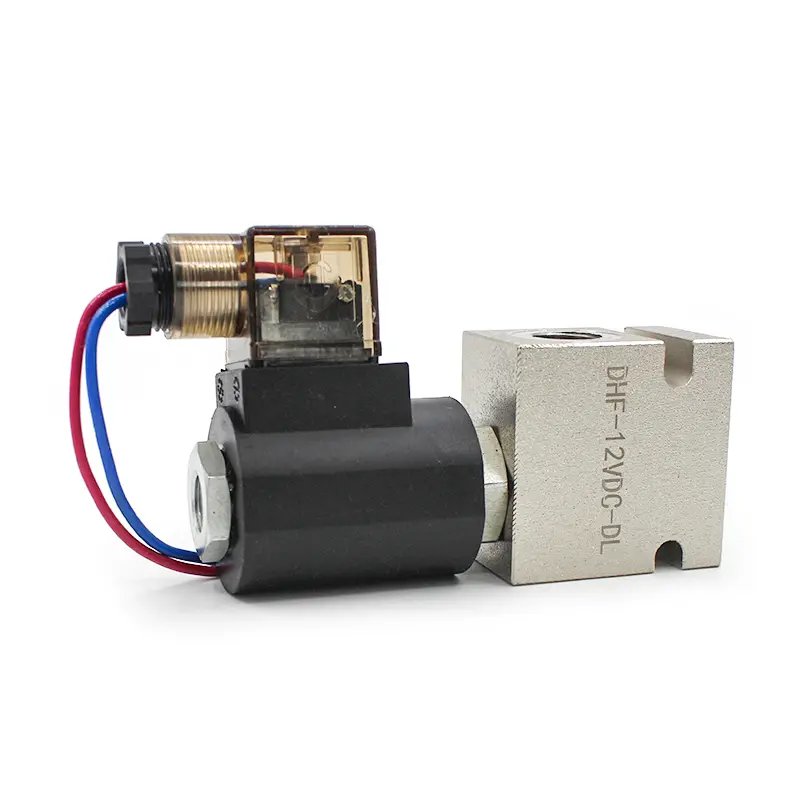

Understanding the internal components of a pilot check valve helps demystify how it works. While designs vary slightly between manufacturers, every pilot-operated check valve contains a few core parts that work in concert to control the flow of fluid. As a factory owner, I emphasize the importance of using high-quality materials for each of these parts, as the failure of any single one can compromise the entire valve.

Here are the essential components:

- Valve Body: This is the outer casing, typically made of steel or ductile iron, that houses all the internal parts. It has ports for the main fluid flow (inlet and outlet) and a separate port for the pilot line. The body must be strong enough to withstand the high pressures common in a hydraulic system.

- Poppet (or Ball): This is the moving part that seals against the valve seat to block reverse flow. The poppet is precision-machined to create a leak-free seal. It is the primary gatekeeper of the valve.

- Spring: A small spring applies constant, light pressure on the poppet, keeping it seated when there is no forward flow or pilot pressure. This ensures the valve closes quickly and prevents backflow the moment forward flow ceases.

- Valve Seat: This is the fixed, hardened surface inside the valve body that the poppet seals against. The integrity of the seal between the poppet and the seat is critical for preventing leakage in the checked position, which is vital for load-holding applications.

- Pilot Piston: This is the component that makes the valve "pilot-operated." It's a small piston that, when exposed to pilot pressure from the pilot line, moves to push the main poppet off its seat. This allows the reverse flow of fluid through the valve. The diameter of this piston relative to the poppet seat area determines the valve's pilot ratio.

Each of these components is a product of precision engineering. The tolerances are incredibly tight to ensure minimal leakage and reliable valve operation over millions of cycles. When you're sourcing a valve, the quality of these internal parts is what truly defines its performance and durability.

Can You Explain the Working Principle of a Pilot-Operated Check Valve?

The working principle of a pilot-operated check valve can be broken down into three distinct operational modes. Understanding these modes is key to grasping how this valve provides such precise control within a hydraulic system. Let's walk through each one.

-

Free Flow Mode: In this mode, the valve behaves just like a standard check valve. Pressurized hydraulic fluid enters the inlet port. The pressure of this fluid easily overcomes the light force of the internal spring, pushing the poppet away from the valve seat. This opens a path, which allows fluid to flow freely through the valve to the outlet port and on to the actuator (e.g., a hydraulic cylinder). There is a small pressure drop across the valve, but the flow is largely unrestricted.

-

Checked (Blocked) Mode: When the fluid flow in the forward direction stops, the spring pushes the poppet back onto its seat, closing the valve. If pressure builds up at the outlet port (for example, from a heavy load on a cylinder), this pressure pushes even harder on the poppet, reinforcing the seal. In this mode, the valve is completely blocked. No fluid can pass from the outlet back to the inlet. This is the crucial load-holding function. The valve will hold this pressure indefinitely, preventing the cylinder from moving or drifting.

-

Pilot-to-Open Mode: This is the unique function of the pilot-operated check valve. To allow the load to be lowered in a controlled manner, a separate pilot pressure signal is sent to the valve's pilot port. This pressure acts on the pilot piston. The piston then extends and physically pushes the main poppet off its seat. This creates an open path for the trapped fluid at the outlet port to flow in reverse, back through the valve to the inlet port, and typically back to the tank. The flow of fluid is now enabled in the reverse direction, but only as long as the pilot pressure is applied. Once the pilot signal is removed, the spring and any system pressure will reseat the poppet, and the valve returns to its checked mode. This is the essence of how this control valve works.

What are the Common Types of Pilot-Operated Check Valves?

Pilot-operated check valves are not a one-size-fits-all solution. They come in various configurations to suit different hydraulic circuit designs and applications. The common types of pilot operated valves are differentiated by their construction and how they manage flow paths. Knowing the difference is important for selecting the right valve for your specific needs.

Here are some of the most common types:

- Single Pilot-Operated Check Valves: This is the most basic configuration. It has a single check valve assembly with a pilot piston to control one flow path. These are typically used in applications where only one direction of an actuator's movement needs to be locked, such as in a simple lifting circuit.

- Double Pilot-Operated Check Valves: This configuration, often called a "dual pilot check," is essentially two pilot-operated check valves integrated into a single valve body. It's designed for controlling a double-acting hydraulic cylinder. One valve controls the flow to and from the rod-end port, while the other controls the piston-end port. The pilot lines are typically cross-connected, so applying pressure to extend the cylinder also provides the pilot signal to release the check valve on the retraction side, and vice-versa. This ensures smooth and chatter-free operation. We offer several types, including our popular Double Pilot Operated Check Valves – Type A.

- Modular and Cartridge Valves: Modern hydraulic systems often favor compact and integrated designs. Pilot-operated check valves are available as cartridge valves, which can be screwed into a manifold block, or as modular valves, which can be stacked with other directional and pressure control valves. This reduces the need for external piping, minimizes potential leak points, and creates a much cleaner and more compact hydraulic system. A great example of this is a Pressure Relieving Modular Valve which integrates multiple functions.

The choice between these types depends entirely on the requirements of the hydraulic circuit. For machinery manufacturers and system integrators, understanding these options is key to designing efficient and cost-effective systems.

Where Are Pilot-Operated Check Valves Used in Hydraulic Systems?

The unique load-holding and safety features of pilot-operated check valves make them essential in a wide range of hydraulic applications across various industries. Anywhere a hydraulic actuator needs to be securely locked in position against an external force, you will likely find this type of valve. Their role is often critical for both the functionality and safety of the machine.

Here are some of the primary applications:

- Load-Holding in Material Handling: This is perhaps the most common use. Equipment like forklifts, cranes, aerial work platforms, and scissor lifts use these valves to hold their loads steady in mid-air. The valve is placed in the line to the lift cylinder. When the operator stops lifting, the directional control valve centers, but the pilot-operated check valve traps the fluid in the cylinder, preventing the load from drifting down.

- Preventing Cylinder Drift: In vertical or angled applications, gravity can cause a hydraulic cylinder to slowly creep or drift, even if the directional control valve is closed, due to small internal leakages in the control valve. A pilot-operated check valve provides a positive, leak-free seal, effectively locking the cylinder in place until it is commanded to move. This is crucial for applications like clamping mechanisms in manufacturing or outriggers on mobile equipment.

- Accumulator Circuits: Hydraulic accumulators store energy in the form of pressurized fluid. A pilot-operated check valve can be used to isolate the accumulator from the rest of the system. The valve allows the pump to charge the accumulator but prevents it from discharging until a pilot signal is given. This provides a source of emergency pressure or a way to absorb hydraulic shocks.

- Safety Circuits: In hydraulic presses or other machinery where personnel safety is a concern, these valves are used to prevent uncontrolled movement in the event of a power loss or hose failure. The valve will automatically lock the actuator in its last position, preventing a heavy press ram from falling.

In all these cases, the pilot-operated check valve is not just controlling fluid; it's ensuring safety, stability, and predictable performance.

What Should You Consider When Selecting a Hydraulic Check Valve?

As a procurement officer or engineer, selecting the correct pilot-operated check valve is a critical decision that impacts the performance, safety, and reliability of your entire hydraulic system. It's not just about finding the cheapest option; it's about finding the right option. Based on my experience helping clients like Mark find the perfect fit, here are the key factors to consider.

- Pressure and Flow Ratings: The valve must be rated to handle the maximum operating pressure and flow rate of your system. Exceeding these ratings can lead to premature failure or catastrophic rupture. Always check the manufacturer's specifications for both continuous and peak ratings.

- Pilot Ratio: This is a crucial parameter. The pilot ratio determines how much pilot pressure is needed to open the valve against a given load pressure. A low ratio (e.g., 3:1) requires higher pilot pressure but offers smoother, more controlled decompression. A high ratio (e.g., 10:1) requires less pilot pressure but can sometimes lead to abrupt or jerky movement if not managed properly. The choice depends on the application and the available pilot pressure in your system.

- Decompression Feature: For systems with high pressures and large volumes of trapped fluid, a valve with a decompression feature is highly recommended. This feature allows the trapped pressure to be released slowly and in a controlled manner before the main poppet opens fully. This prevents "decompression shock," a violent hydraulic shockwave that can damage components and cause jerky operation.

- Materials and Seals: The valve body material (e.g., steel, ductile iron) and seal material (e.g., Buna-N, Viton) must be compatible with the hydraulic fluid being used and the operating environment. Factors like temperature, fluid type, and external conditions (e.g., saltwater exposure) will dictate the best materials to ensure a long service life for the valve.

- Certifications and Quality: This is a non-negotiable point for me and my business. Always source valves from a manufacturer who adheres to international quality standards like ISO 9001. Ask for documentation and test reports. A reliable supplier will be transparent about their quality inspection processes, ensuring you receive a durable and safe valve. This protects you from counterfeit components and ensures the valve performs as specified.

How Do You Troubleshoot Common Issues with a Pilot Check Valve?

Even the highest quality hydraulic valve can encounter issues in the field due to contamination, wear, or incorrect system setup. Being able to diagnose common problems with a pilot check valve can save significant downtime and maintenance costs. Here’s a quick troubleshooting guide based on problems we’ve helped our customers solve over the years.

Problem 1: The valve is leaking or the load is drifting down.

- Possible Cause: The most likely culprit is contamination. A small piece of dirt, a metal shaving, or a piece of a failing seal can get lodged between the poppet and the valve seat, preventing a positive seal.

- Solution: In some cases, cycling the valve under pressure can dislodge the debris. If that doesn't work, the valve will need to be carefully removed, disassembled, cleaned, and inspected for damage to the poppet or seat. Worn or damaged seals should also be replaced.

- Prevention: Proper hydraulic fluid filtration is the best prevention.

Problem 2: The valve will not open with a pilot signal.

- Possible Cause: The issue could be a lack of pilot pressure. This might be due to a blockage in the pilot line, a problem with the directional control valve that supplies the pilot signal, or a pilot pressure that is too low to overcome the system pressure (related to the pilot ratio).

- Solution: First, verify that you are getting adequate pressure at the pilot port using a pressure gauge. Trace the pilot line back to its source to check for kinks or blockages. Ensure the pilot pressure meets the requirements specified by the valve manufacturer for your load conditions.

Problem 3: The operation is jerky or noisy (hydraulic shock).

- Possible Cause: This is often a sign of decompression shock, especially in high-pressure systems. When the pilot check valve opens instantly, the compressed fluid expands rapidly, creating a shockwave.

- Solution: The best solution is to use a pilot-operated check valve with a built-in decompression feature. If your current valve does not have one, you may need to replace it with one that does. Alternatively, modifying the circuit to slow down the application of pilot pressure can sometimes help mitigate the shock.

Why Partnering with a Reliable Hydraulic Valve Manufacturer is Essential?

In a global market, you have endless choices for sourcing components like a hydraulic valve. However, as a business owner like Mark Thompson knows, the real cost of a component goes far beyond its initial price tag. The long-term costs of downtime, missed deadlines, and safety incidents due to a faulty valve can be enormous. This is why choosing the right manufacturing partner is one of the most important business decisions you can make.

From my perspective as Allen, a factory owner who exports globally, reliability is built on three pillars:

- Uncompromising Quality and Transparency: A trustworthy manufacturer doesn't just claim quality; they prove it. This means rigorous quality control at every stage of production, from raw material inspection to final pressure testing. It means providing clear, verifiable certifications like ISO 9001. We understand the pain of receiving components with fraudulent certificates, which is why we welcome factory audits and provide complete documentation for every valve we ship. This transparency builds the trust needed for a long-term partnership.

- Clear and Efficient Communication: Inefficient communication is a major pain point. Misunderstandings about technical specifications, payment terms, or shipping schedules can cause costly delays. You need a partner whose sales and technical teams are responsive, knowledgeable, and fluent in your language. At our company, we invest in a professional team dedicated to ensuring that your questions are answered promptly and your requirements are understood perfectly, whether you are a technical expert or a sales-focused professional.

- Logistical Excellence: A high-quality valve is useless if it doesn't arrive on time. Shipment delays can halt your entire production line. A reliable supplier understands the importance of logistics. They have robust processes for packaging, documentation, and tracking to ensure your order arrives on schedule and in perfect condition. We work closely with our logistics partners to provide realistic delivery timelines and keep you informed every step of the way, so you can manage your production schedules with confidence. Partnering with a factory that controls its own production lines, like ours, ensures greater control over these critical factors.

Ultimately, a partnership with the right hydraulic valve manufacturer isn't a transaction; it's an investment in the quality, safety, and reputation of your own products.

Key Takeaways to Remember

- Function: A pilot-operated check valve allows free flow in one direction and blocks reverse flow, but it can be signaled to open and allow reverse flow via a pilot pressure line.

- Purpose: Its primary use is for safely holding hydraulic loads in position, preventing actuators from drifting or moving unintentionally.

- Key Feature: The pilot ratio is a critical specification that determines how much pilot pressure is needed to open the valve against the trapped system pressure.

- Selection is Crucial: Always select a valve based on your system's pressure, flow rate, fluid type, and application needs. Consider features like decompression for high-pressure circuits.

- Applications are Everywhere: These valves are essential safety and control components in material handling equipment, construction machinery, hydraulic presses, and accumulator circuits.

- Supplier Reliability Matters: Partner with a manufacturer who guarantees quality with verifiable certifications, offers clear communication, and ensures on-time delivery. The right valve from the right partner is fundamental to the success of your hydraulic system.